|

|

|

|

|

|

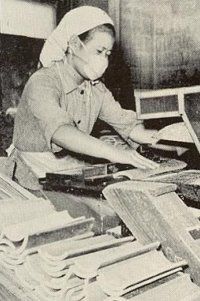

(1) Selection: Pieces of bamboo, which is the main material for slide

rules, undergo quality inspection.

|

(2) After selection and rough cutting, pieces are formed using circular

saw.

|

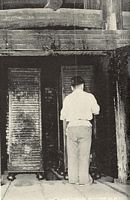

(3) Heating process: Pieces are heated for long period of time at

constant temperature.

|

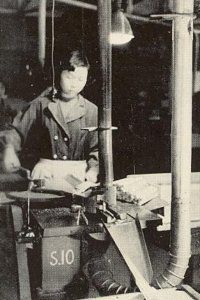

(4) After gluing two or four pieces together, a flat surface is

milled out using this machine.

|

(5) A block is split in half using circular saw, thus making two slide

bars at the same time.

|

(6) Sheet of Celluloid is glued and pressed. Student rules are not

covered with Celluloid on all sides, but are treated with a hard vanish.

|

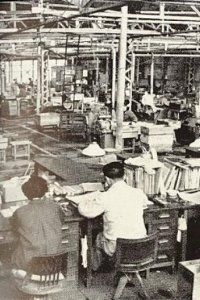

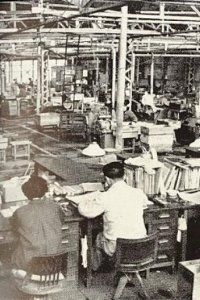

(7) Overview of the factory. Hundreds of special purpose machines

are lined up.

|

(8) Overview of the factory. This is where slide rules are

manufactured for shipping world wide.

|

(9) Inspection: Checking thickness with micrometer.

|

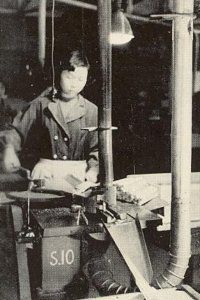

(10) Making grooves: It requires great attention since this is

one of the areas on which accuracy of the slide rule depend.

|

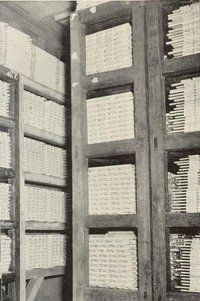

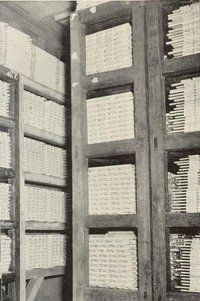

(11) Seasoning: Seasoning gives dimensional stability of

the stock. It is one of the key processes and can not be neglected.

|

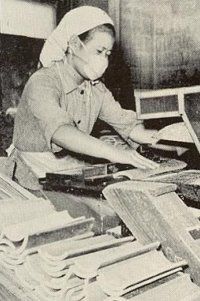

(12) Finish: After red markers are put in, and after inspection,

the surfaces get polished.

|

(13) In some rules, there is an index line on the back of the rule.

Since accuracy is required, a line curving machine with

microscope is used.

|

(14) Cursor line is created by first coating surface of cursor glass

with wax and drawing a thin line and finally etching the glass.

|

(15) Assembly of two-sided cursors: Two sided cursors are the most

difficult to assemble.

|